Effective Use of Wall-Mounted Fans in a Warehouse

Effective Use of Wall-Mounted Fans in a Warehouse

Managing temperature and airflow in a warehouse is crucial for maintaining a productive and safe working environment. Wall-mounted fans are an effective solution for improving air circulation, reducing heat buildup, and ensuring comfort. This guide explores the practical aspects of using wall-mounted fans in a warehouse, from installation to maintenance.

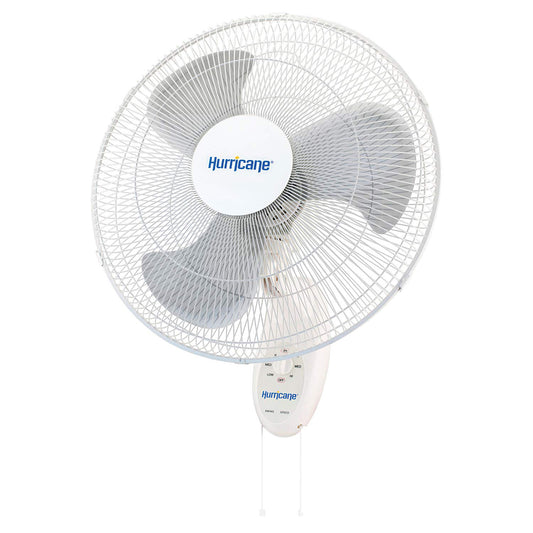

An example of an industrial wall mounted fan: Hurricane 20" Pro Commercial.

Understanding Warehouse Ventilation NeedsWarehouses are often large, open spaces that can become hot and stuffy, especially if they house heavy machinery, inventory, or high-density storage. Proper ventilation is necessary to:

- Prevent heat buildup

- Reduce humidity

- Enhance air quality

- Maintain a comfortable working environment

Further complicating airflow is the fact that many warehouses, workshops and similar buildings have high ceilings with very large cubic areas of space and air that need to be moved. Basic business air ventilation and airflow solutions often fall short for industrial spaces and buildings.

Choosing the Right Wall-Mounted FanBefore installation, selecting the appropriate wall-mounted fan is crucial. Consider these factors:

- Size and Power: Choose a fan size and power that suits your warehouse's dimensions and ventilation needs. Larger warehouses might require high-velocity fans, while smaller areas could benefit from standard models.

- Airflow Capacity: Measured in cubic feet per minute (CFM), airflow capacity determines how effectively a fan can circulate air. Calculate the required CFM based on the warehouse size and the number of fans needed. For fans, CFM is ultimately decided by the fan blade size and motor speed. The larger the fan blade, the higher the CFM airflow capacity, but also the larger motor needed to run the fan.

- Durability and Build: Warehouse environments can be harsh, so opt for fans with robust construction, corrosion-resistant materials, and durable blades. Keep in mind what types of debris permeate the air in your facility. Things like saw dust, gas or powder chemicals, oil, water vapor, flour or other food by products require more robust fans to help clear the air.

Effective placement ensures optimal airflow and cooling. Follow these tips for strategic fan placement:

- High and Away from Obstacles: Mount fans high on walls, ideally near the ceiling. This placement allows them to circulate air throughout the space and avoids obstruction from inventory or machinery. Wall fans are especially great around areas with lots of foot traffic because they help eliminate wires and other tripping hazards.

- Even Distribution: Space fans evenly across the warehouse to ensure uniform airflow. This avoids creating hotspots and cold spots, which can affect worker comfort and efficiency.

- Near Heat Sources: Position fans near heat-generating equipment or areas with high foot traffic. This helps dissipate heat and maintain a consistent temperature. Be aware of doors, windows and draft areas that may increase or reduce a particular fans efficiency.

Installation Guidelines

Proper installation is key to maximizing the effectiveness of wall-mounted fans. Follow these guidelines:

- Wall Strength: Ensure the wall where the fan will be mounted is structurally sound. If necessary, reinforce the wall to support the fan’s weight and vibrations. Most Hurricane wall mounted fans are designed to work without additional reinforcement on the majority of industrial wall surfaces.

- Height and Angle: Install fans at a height where they can effectively circulate air but are out of reach to prevent accidents. The angle of the fan should be adjustable if possible, allowing you to direct airflow as needed. Look for full wall mount 90 degree oscillating fans to more evenly distribute air throughout your space.

- Electrical Considerations: Fans should be wired according to electrical codes. If unsure, consult a licensed electrician to ensure proper installation and safety. Hurricane fans are designed to simply plug into existing wall sockets, making them easy and affordable to set up. Many industrial ceiling fans need to be properly wired by an electrician or properly trained building maintenance manager.

Maintenance and Safety

Regular maintenance ensures fans operate efficiently and safely:

- Clean Regularly: Dust and debris can accumulate on fan blades and grills, reducing performance. Clean fans regularly using a dry cloth or a vacuum with a brush attachment. For thorough cleaning, disconnect the fan and use a mild detergent. This is most important for areas with lots of particulate matter in the air from their manufacturing or production processes.

- Check for Damage: Regularly inspect fans for any signs of wear and tear, such as frayed wires, loose mounts, or damaged blades. Address any issues promptly to prevent accidents.

- Lubricate Bearings: If the fan has bearings that require lubrication, follow the manufacturer’s recommendations for type and frequency of lubrication.

- Focus on Metal Components: All Hurricane Pro and Commercial grade fans feature robust metal components and motors that are designed for heavy continuous use. If you use cheaper plastic component fans, understand that the components will wear out much faster in a work setting where they are getting used constantly.

Wall-mounted fans are relatively energy-efficient compared to air conditioning systems, but there are ways to optimize their cost-effectiveness:

- Use in Conjunction with Other Systems: Combining fans with other cooling methods, such as evaporative coolers or ventilation systems, can enhance overall efficiency.

- Timers and Controls: Install timers or programmable controls to operate fans only when needed. This reduces energy consumption and lowers operational costs.

- Regular Maintenance: Proper upkeep prevents costly repairs and ensures fans continue to operate efficiently. Focusing on fans with robust components will ensure a higher energy efficiency and longer life before needing to repair or replace parts.

Safety Considerations

Safety is paramount in warehouse environments. Adhere to these safety practices:

- Secure Installation: Ensure fans are securely mounted to prevent them from falling or shifting, which could pose a risk to workers.

- Guard Installation: Install fan guards to prevent accidents involving rotating blades. Most wall mounted fans come with fan blade baskets already, but most ceiling fans don’t.

- Electrical Safety: Regularly inspect electrical connections and wiring to prevent electrical hazards.

Effective use of wall-mounted fans contributes to a more comfortable working environment:

- Temperature Regulation: Fans help regulate temperature, reducing the risk of heat stress and improving overall comfort.

- Improved Air Quality: Better airflow helps disperse dust, fumes, and other airborne particles, contributing to healthier air quality.

- Increased Productivity: Comfortable workers are more focused and productive. By reducing heat and improving air circulation, fans can help maintain a productive work environment

Real-world examples illustrate the effectiveness of wall-mounted fans in warehouse settings:

- Logistics Warehouse: A large distribution center installed high-velocity wall-mounted fans strategically across the facility. The result was a significant reduction in temperature and improved air circulation, leading to increased worker comfort and efficiency.

- Industrial Food Production Line: A warehouse dealing with heat-sensitive food products products used fans to manage temperature fluctuations. The fans helped maintain a stable environment, reducing spoilage due to humidity and mold and improving product quality.

Wall-mounted fans are a valuable tool for enhancing ventilation and temperature control in warehouses. By choosing the right fans, placing them strategically, and maintaining them properly, you can create a more comfortable and efficient work environment. Regular attention to installation, maintenance, and safety ensures that these fans serve their purpose effectively, contributing to both worker satisfaction and operational success.